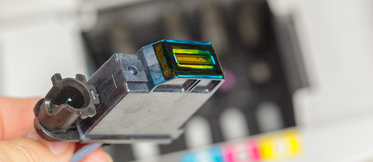

Do you want to know which are the parts of a toner?

By now, we all know what is a toner and what it is for, but do we know which are its components? Surely many of you are now visualizing it in your mind and trying to identify all of them. In today's article we are going to analyse them so that, once and for all, everything about this for the printer so important product is clear.

Which is the technology present in this type of cartridges? Here we have the toner container, the seal, the cleaver, the magnetic roller, the cleaning blade, the primary charge roller and the cylinder unit. As you see, there are a lot of components, but we always hear about the toner dust. So, come and discover with us what every part is for.

Toner container

This container contains the toner dust, that will later be magnetically absorbed by the printing paper.

Seal

It is a strip that serves to protect the ink dust. Thanks to this seal, the toner will not spill before the installation.

Cleaver

Thanks to this cleaver, the amount of toner dust that passes through the magnetic roller can be regulated. Due to the passage of time and the continued use, this part can wear out and cause printing problems by creating lines.

Magnetic roller (mag roller)

Thanks to this roller, the dust will be transferred from the toner container to begin the printing process. The roller has a Teflon coating to prevent the toner from sticking. This process is performed through an electrostatic charge.

Waste toner box

It is a small box that collects excess toner after printing. Do not think that for this reason we will have more toner, because it cannot be reused.

Cleaning blade

This part is closely linked to the waste toner box, because it cleans the toner that has not been transferred to the paper and it brings it to the waste box. Over time it is the cause of the wear on of the cylinder unit. Specifically, it is a polyurethane sheet assembled on a metal rail.

Primary charge roller

Metal shaft with a shaper rubber around it that tries to bring electricity to the surface of the cylinder. In this way, the laser can write on the cylinder that uses an electric signal so that it can repeat it again.

Cylinder unit

These cylinders (green or blue) have gears at each end of them, which allow them to roll. The cylinders are composed of three layers:

Prime layer: it functions as adhesive between the aluminium and the inside wall of the cylinder.

Charge-generation layer: it generates charges on the surface so that the toner dust clings to the paper.

Cargo transport layer: it manages that the laser comes into contact with the charge-generation layer.

Thanks to all these components, the toner can exercise its role in the printer and becoming an indispensable element for its functioning. Now we know what is behind this consumer appliances beyond the well-known toner dust.